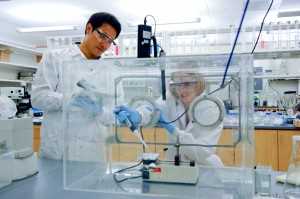

Careers in chemical engineering are sometimes exciting, always demanding, and ultimately provide a sense of accomplishment and achievement. Chemical engineers create, develop, and apply processes in which molecules undergo changes in chemical structure, physical state, or temperature. In many ways, chemical engineers are modern day alchemists.

Instead of turning lead into gold, however, they design and operate processes which, for example:

- convert crude oil into cosmetics, pharmaceuticals, petroleum products, automobile tires, synthetic fibers, dyes, and plastics;

- prevent pollutants from entering the air and water and recover valuable chemicals;

- transform agricultural material into high fructose corn syrup (beverage sweetener), ethanol, and many food additives; and

- manufacture textiles, personal care products (shampoo, soaps, pain relievers), microchips, paper, paints, and all manner of chemicals.

There is a definite distinction between chemical engineers and their nearest scientific relatives, chemists. Chemists are primarily concerned with whether a molecule can be synthesized at all and what series of steps might achieve the highest yield of final product. Chemical engineers, on the other hand, are focused on minimizing the generation of environmental pollutants, and manufacturing the product inexpensively, safely, and in sufficient quantity and purity to meet the needs of the consumers and the requirements of regulatory agencies. This description indicates the broad range of issues and areas in which chemical engineers might find themselves involved. Treating environmental pollutants, analyzing the economics of a process, and accounting for the health and safety issues of products and processes are just some of the functions undertaken by chemical engineers.

Another aspect of chemical engineering which differs significantly from other science and engineering disciplines is process operation. The manufacturing process must be controlled such that the product meets or exceeds regulatory and customer specifications. Chemical engineering involves sufficient understanding of manufacturing, often to the point of developing mathematical models of those processes, such that control schemes can be designed and implemented. Without such control, one would never be sure if this week’s batch of ibuprofen is as effective (or safe) as last week’s, or if this month’s microprocessor performs identically to last month’s chips.

Courses include:

Chemical Process Principles, Chemical Process Systems, Transport Processes I & II, Chemical Process Thermodynamics, Thermodynamics of Chemical & Phase Equilibria, Process System Control & Analysis, Design & Analysis of Chemical Reactors, Senior Design Project – This project is a semester-long team activity involving chemical process design and optimization with consideration of economic and technical factors in process development, site selection, project design, and production management. A written report and presentation are included.

Additional Information:

In’s and Out’s of Engineering CODA

Video-Engineering Majors Exploration

Video-The Creativity of Engineering at NC State

CODA Statistics-Students Accepted into College of Engineering Majors

14 Grand Challenges for Engineering

| College | |

| Discipline |

|

| Academic Department |

|

| Departmental Contact | |

| Major Overview | |

| Plan Requirements |

|

| Semester Sequence |

|

| Related Majors | |

| Skills You Could Develop |

|

| Learn More About This Major | |

| Career Titles | |

| Learn More About Careers |